What makes good air curtain?

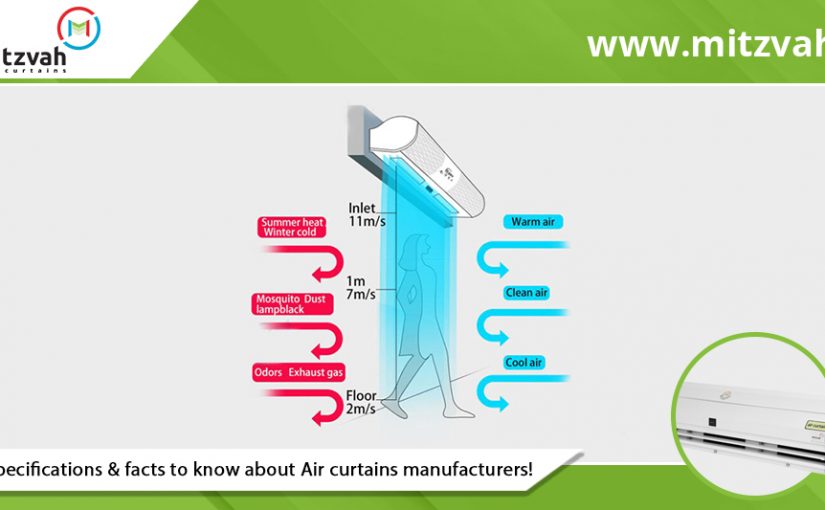

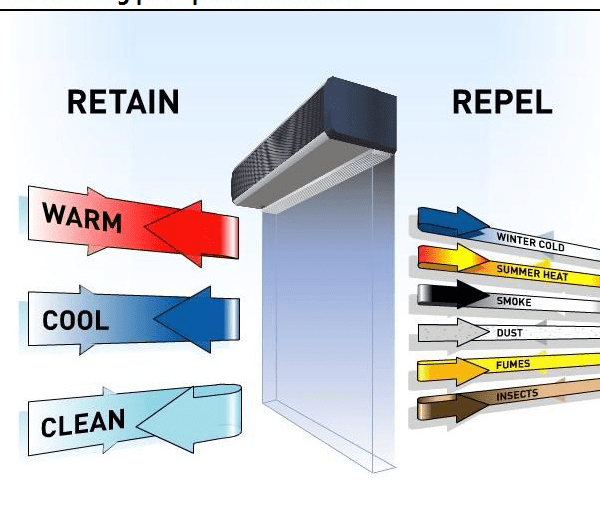

An Air curtain technically, is a fan-powered air device that automatically creates an invisible air barrier wherever it is being installed. It is mostly used over the doorway to separate efficiently two different environments and it makes this separation without limiting or interrupting the access of the people or vehicles on the premises. Air curtain manufacturers make sure that they are highly operational and progressive.

There are many Air curtain manufacturing units and their worldwide users but not all are fully aware and familiar with its usage and specifications. Thus, we have listed some characteristics and tips that all users should keep in mind to choose the right product.

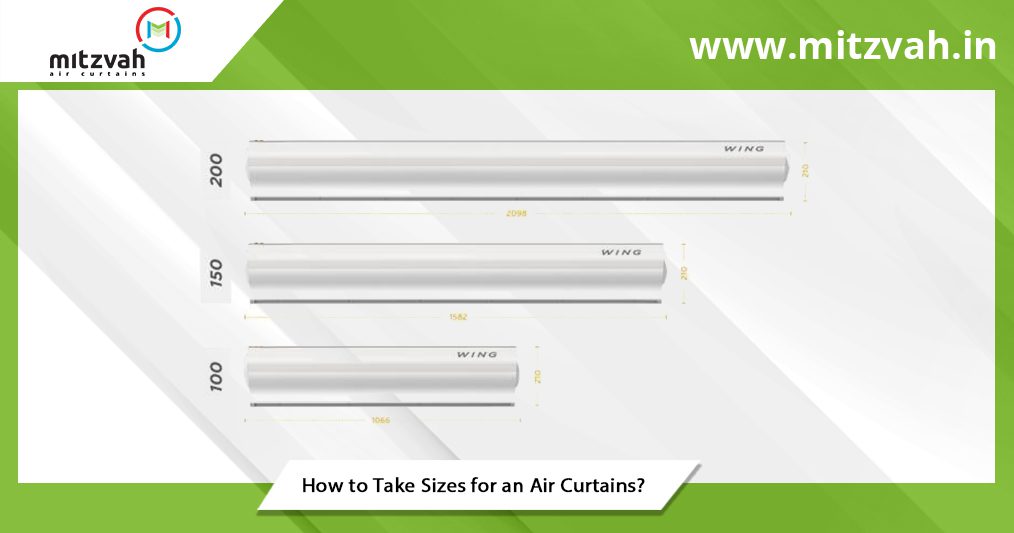

- The first and foremost important thing is the height of the door

- Choose an air curtain according to the width of the door

- The location of the building should be the determinant factor for the level of protection needed against weather conditions

- Use air curtains if the focused building has several doors in the same area,

- If the building has several stories connected by escalators/stairs

- Air curtains are best to measure pressure differences between the inside and outside of the building

- Door characteristics also matter to choose an air curtain, if frequently closing and opening, then go for sensor based device, or else manual.

- Characteristics of the ventilation and air conditioning installation

- Voltage and electrical power availability also affect the performance of air curtain

- What type of business, location, and office equipment are there is also vital to get the appropriate product.

- The fitting style of an air curtain is also responsible for its performance such as free hanging or recessed, horizontal or vertical installation, heated or unheated, etc.

Air curtains and their manufacturing specifications

However, there are different sorts of air curtains available as per the industry usage. So, herein we have mentioned some of them for your information and knowledge.

Types of Air Curtains:

There are majorly four broad categories of air curtain to cater to the different usages and requirements of the customers. They are as follows:

- The very first type of Air Curtain with a velocity of 15-17 meters/sec, the basic usage is to create only a thermal barrier.

- Another one is Air Curtains with a velocity of 17-19 meters/sec. Their primary purpose is to control dust, pollution, and insects in varying degrees.

- The next type of Air curtain with a velocity of 20-22 meters/sec and they act as a device that controls dust, pollution, and insects in varying degrees

- Special Purpose Velocity Air Curtain has 26 meters/sec & above and it is specifically required where a high degree of pollution and insect control is needed. They are perfect for industries such as canning, bakeries, dairies, pharmaceuticals, distilleries, and cold storage.

Some Air curtain manufacturers in India are:

- Mitzvah

Mitzvah Air Curtains are duly designed in the most professional ways to provide uniform air with minimum noise and no wobbling. Our products are thoroughly tested at labs and meet the highest quality standards to provide customers a trouble-free service& experience. The Air Curtains mostly do not require any post services if the usage is clear and adequate. In order to meet the low noise requirements for conference rooms, operation theatres, and computer rooms among others, Air Curtains also come in acoustically treated models to meet such requirements. The Air Curtains are especially suited to meet the requirements of hotels, restaurants, fast food centers, distilleries, and pharmaceutical industries where the entry of mosquitoes and flies needs to be curbed.

2) Mitsubishi

Mitsubishi Electric India Pvt. Ltd. was effectively incorporated in 2010, and since then they strive for manufacturing the best products among other competitors. They focus on realizing the potential and needs of customers to fulfill the requirement of Indian households. Mitsubishi Electric is one of the top Air Curtains Manufacturers that are perfect to maintain a comfortable, clean and hygienic environment while also saving energy with a quiet, efficient, and powerful operation.

3) Euronics

Euronics is a major Exporter, Supplier, and Air Curtains Manufacturer in New Delhi. Air Curtains have now become a necessary part of air-conditioned areas as they act as the premier thermal barriers. They are primarily to prevent dust and pollution, but they are capable of giving additional services as well. Air Curtain is custom-made units given as per different requirements. The cabinets of these products are made of cold rolled mild steel sheets which are duly powder coated or are made with Stainless Steel as per the usage &requirement. Whereas the blowers are made of high-quality aluminum/plastic fiber both statically as well as dynamically on computerized digital balancing machines.

4) SudhaiAirTech

Sudhai Air Tech has been one of the best air curtain manufacturers and projector companies that provide the most efficient, cost-effective, reliable technical products in the market.

They have headquarters in Mumbai, Maharashtra. The company not only manufactures products but also offers expert advice on air curtain projects, system design, supply, service, after-sales support, etc.

Their wide-ranging products cover everything from economical air curtains used in medium size shops, complexes &doorways to large industrial units for warehouses and workplaces. The products are sold in various color options beautifully designed &crafted products for prestigious buildings and stores. Sudhai Air Curtains stand out from other products as they have slim, simple mounting, high power & durable airflow.