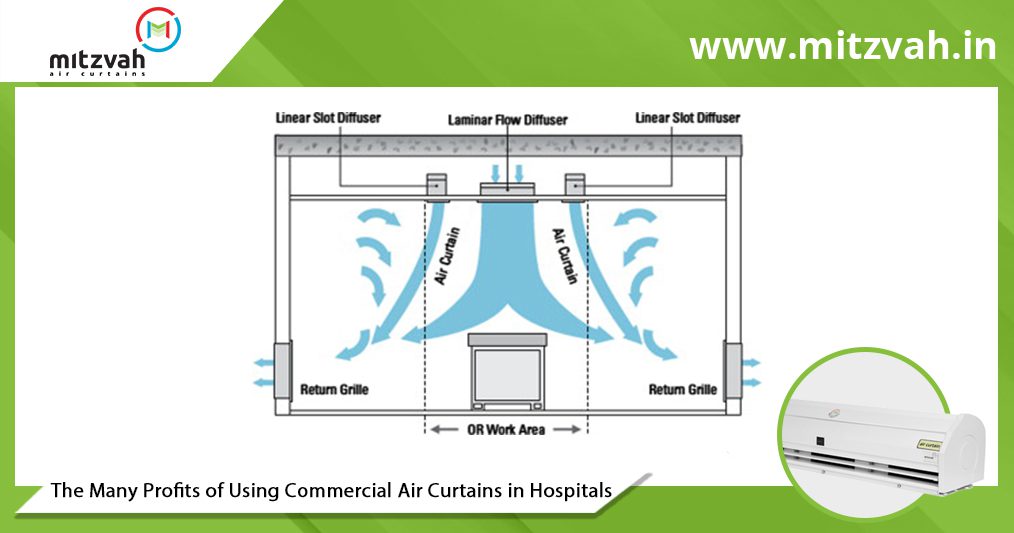

Hospitals have challenging and crucial environments, not just for the doctors and nurses who work hard every day to save lives and provide a high standard of care but also for the patients. Managing the logistical demands of large healthcare complexes is challenging, from controlling energy usage to monitoring air quality to ensuring patients have access to food prepared in a hygienic setting. so air curtains in hospitals are great options for patients.

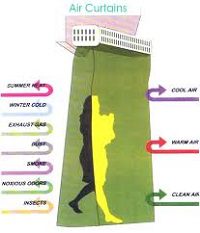

An air curtain, additionally regarded as an air door, is a machine that blows a managed movement of air throughout an opening to the different facets to create an air seal. Because they assist to include heated or conditioned air, they supply tremendous strength financial savings and extended non-public alleviation when utilized in industrial or industrial settings. They additionally assist to cease the infiltration of pollution and flying insects.

Do Air Curtains Keep Flies Out?

Yes! and mosquitoes, yellow jackets, and bees too. Air curtains, from time to time referred to as fly fans; furnish an excessive speed flow of air throughout a door or window opening that maintains pests like bugs from coming into the building. These flies and different small insects discover the air circulates too effectively for them to fly via and if they try, they are blown down or sideways earlier than they can enter the building.

How Do Air Curtains Work?

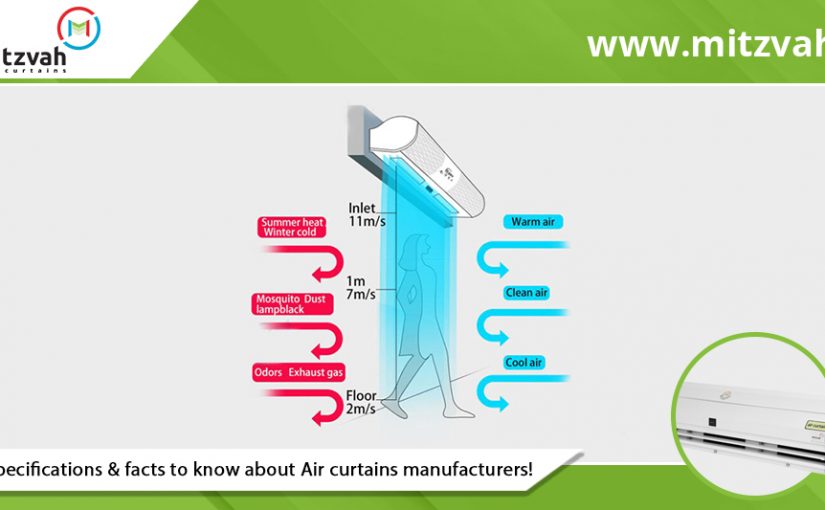

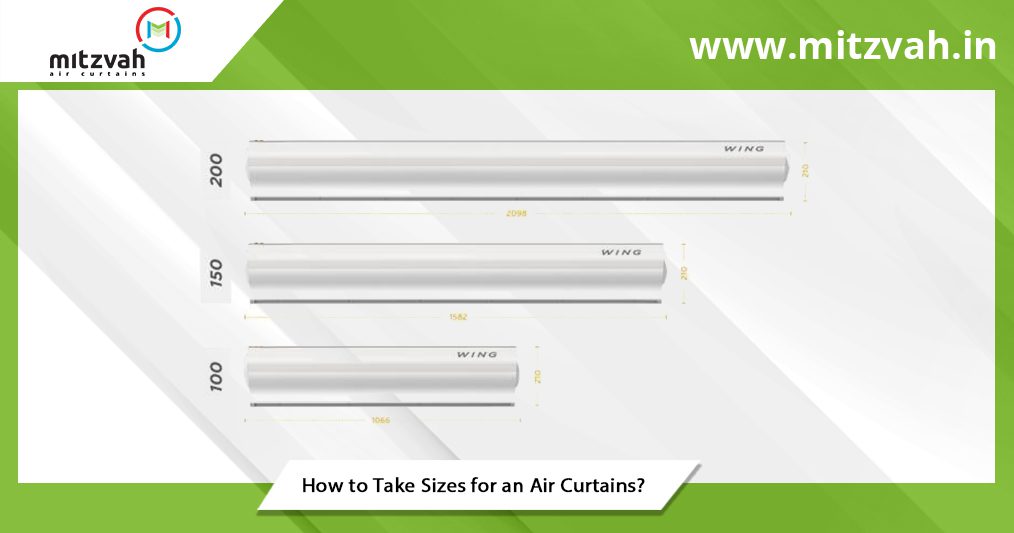

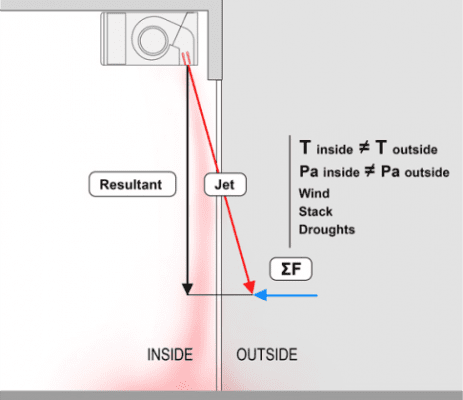

There are two solutions to this question, thanks to the truth that there are two wonderful sorts of air curtains. The first kind is known as a non-recirculating air curtain. These air curtains have a tendency to be the most famous amongst many organizations due to the fact they are much less high-priced to set up and value much less to maintain. The second kind is known as a recirculating air curtain. These air curtains fee greater cash to install and keep however are additionally extra effective and superb as air barriers. These air curtains have a tendency to be perfect for entrances with strangely excessive tiers of foot traffic.

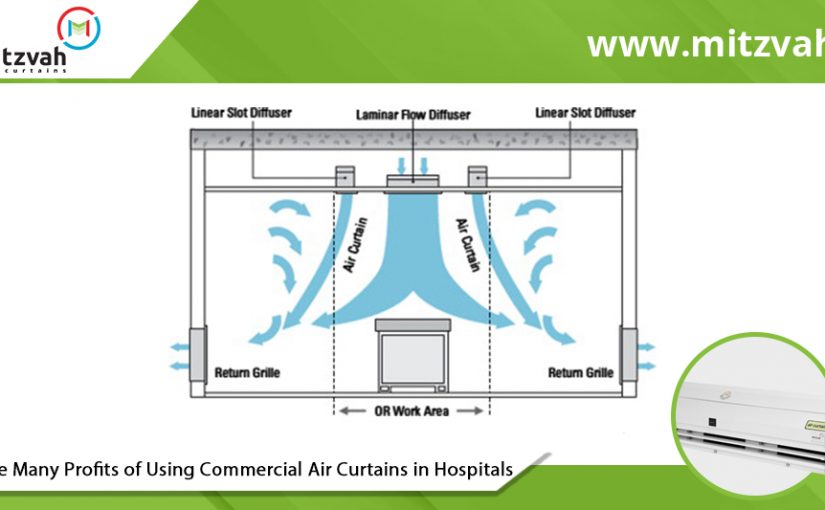

Both sorts of air curtains carry air into the device via an intake grille and then use a fan to propel or speed up the air. The air passes via what is referred to as a plenum, which helps evenly distribute it and make certain a constant movement of air alongside the complete size of the air curtain. Since most air curtains are set up at the pinnacle of a door opening, the air then shoots down; masking the opening with what is, in fact, a waterfall of air.

Non-recirculating air curtains solely consist of a pinnacle unit, which sits above a door or opening and discharges air downward. Recirculating units, meanwhile, appear like high-tech doorframes or metallic detectors. They have a full rectangular or rectangular layout that spans all aspects of the door opening. This format lets in the air discharged at the pinnacle of the air curtain to be accrued at the backside of the curtain and recirculated lower back to the top.

What are the profits of using Air Curtains?

We have already touched upon the fundamentals make use of air curtains, however for a refresher; they commonly fall into three important categories:

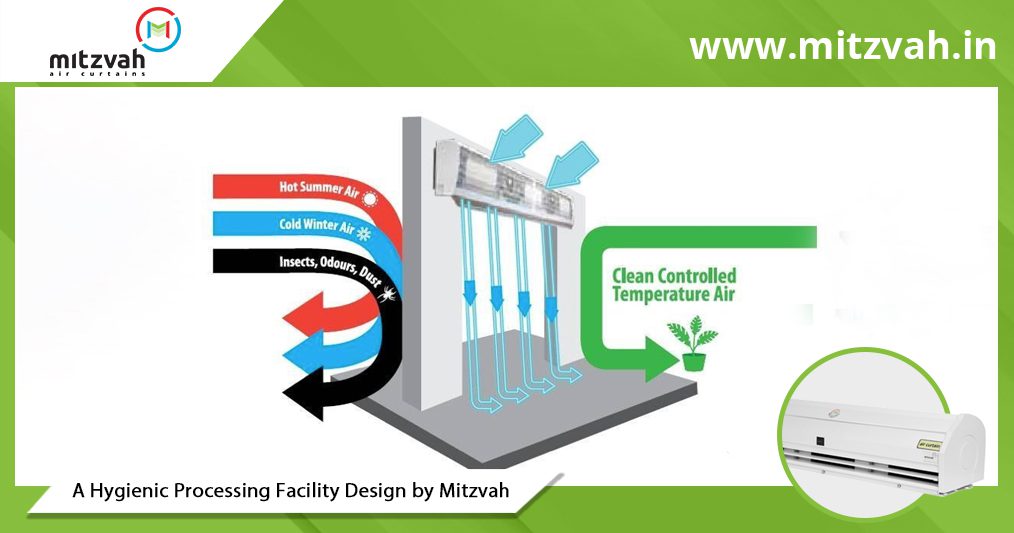

Climate control:- Climate management is probable the pinnacle software for air curtains amongst most industrial enterprises. In groups the place human beings are continuously going in and out, or the place leaving a door open simply makes feel for enterprise purposes, there is usually the chance of warmness transfer. Both occurrences will purpose your HVAC gadget to work that ton more difficult to attain the temperature you have set on your thermostat.

Flying insect and particle control: – Flying insect and particle manipulation is brilliant as well. In the summertime, winged bugs such as flies, gnats, bees, and mosquitoes can fly thru open doorways and home windows and terrorize your personnel or customers. Air curtains let you experience a fantastic open-air sense in your institution whilst nonetheless understanding that these flying bugs are going to be blasted out of the air if they strive to go via the air curtain.

Comfort: – A Comfort Air Curtain from Biddle will grant an energy-efficient answer for your industrial requirements. An air curtain no longer acts as a bodily barrier, however stipulations incoming air and reduces the quantity of heat air escaping from the building. An air curtain ought to consequently decorate alleviation and shop energy.

Where Are Air Curtains Used?

Virtually any commercial enterprise can gain from an air curtain in one way or another. Issues such as warmth transfer flies that won’t go away, dirt or pollen, and drafty air are now not sequestered to any one industry. Instead, these problems can have an effect on any employer in any field, making the doable functions for air curtains almost unlimited.

- Food Service (Quick Serve, Restaurants, Schools & Cafeterias)

- Retail & Office

- Convenience & Grocery

- Healthcare & Hospitals

- Manufacturing, Warehouse & Distribution

- Transportation & Terminals

- Indoor Grow Facilities & Processing Plants

- Food Processing Plants

- Residential

- Aircraft Hangers

Mitzvah is provided with commercial air curtains in hospitals and healthcare centers. There have good quality and anti-hygiene air curtains for hospitals.