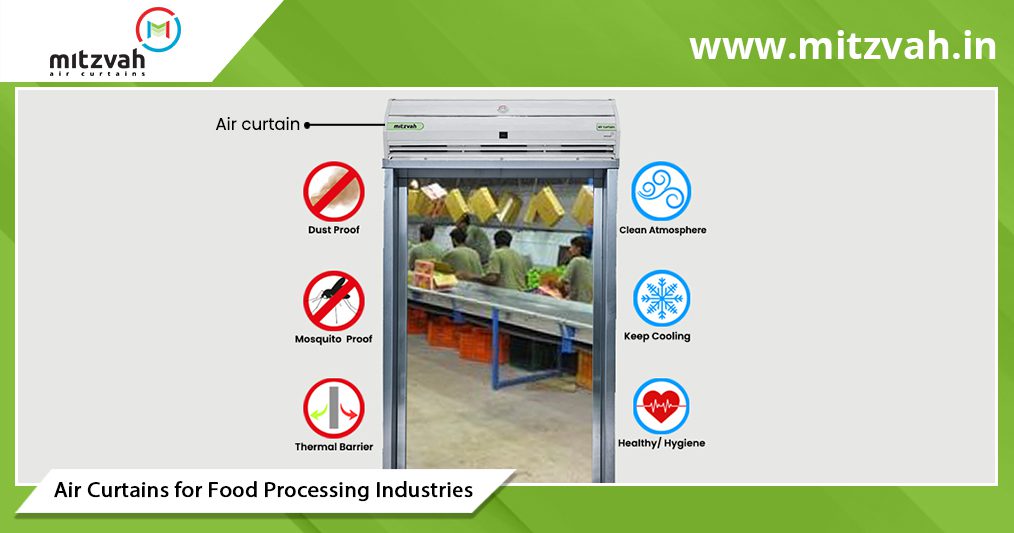

In food processing facilities, air curtains for food processing industries do more than just maintain the temperature

While an air curtain may be useful for the majority of businesses, food processing facilities face a unique set of challenges. In order to comply with the standards imposed by several organizations, including the Food and Drug Administration, these facilities must routinely keep certain sections cool and insect-free. This is because they must adhere to a variety of rules and procedures. Compliance with rules is important for the success of any company that processes food, and installing an air curtain is a good way to do that.

Installation of an air curtain allows food processing facilities to keep their entrance door open during work hours without worrying about the building overheating. By leaving the doors of a grocery store or other business open, the business becomes more welcoming to consumers and safer in the event of a fire or other emergency. Heating and cooling costs, which would otherwise be too high for most businesses, are also reduced.

- Air curtain: a controller of pests

- Helps in keeping the ambience clean

Insect and pest infestations are the worst nightmares of every food processing plant. Insect infestations are common in food processing plants that aren’t protected because insects tend to gather in places like that.

Smoke, odors, and bugs are all filtered away by air curtains. An air curtain lets businesses store perishable goods without worrying about cross-contamination. It improves the whole environment for shoppers, including their health and safety.

A filthy food processing factory is the single greatest source of possible contamination in the food supply. The ability to maintain a clean and sanitary processing area is critical for maintaining a quality environment and product and remaining in compliance with applicable regulations. By being easily cleaned and not susceptible to corrosion, air curtains save time and effort during the cleaning process for both business owners and personnel. Infection and mould development are both likely to occur in a food processing facility.

There will be no complaints or discomfort from those waiting in line to pay. Loading docks, stockrooms, and other facilities will be kept clean and hygienic if harmful substances are prevented from entering the building when an air curtain is used at every entrance of the food processing plant or food mart.

Important factor while mounting an air curtain in a food processing facility

When choosing an air curtain, one of the most essential considerations to make is whether or not it fully covers the entrance. This should be done even if there is some overlap on both sides of the curtain, as this will guarantee optimum performance and block all possible access points for insects.

Air curtains may be installed either inside or outdoors; however, it is recommended that they be used outside to section off areas that are prone to infestation by insects. In addition to fending off insects, these air curtains may also deter rodents, as food attracts all types of rodents that can compromise the hygiene of the food mart or food facility. This is because, as shown by a number of studies, the feeling that is produced by the air curtain’s air on the skin of rodents is repellent, and they avoid it.

Drying times will be cut down with the use of air curtains

Air curtains might be useful in cold storage food facilities for handling moist floors, ice, and condensation. Since the interior of the cold storage is much colder than the outside, ice and condensation have formed at the entrances. As a result, there might be a lot of leaking and other strange concerns, particularly in humid areas. A facility’s cold storage food market’s customers and employees are put in danger as a result of all of these factors. Air curtains are meant to reduce the effects of these hazards, making the workplace safer for employees.

Air curtains may also help speed up the drying process for leakage, wet floors, and mechanical tools. For the purpose of drying, a commercial dryer is required, which will require a substantial amount of space to adjust. As a result, they are not practical for enterprises of any size. The question is, “What’s the cure for this?” The only help we can receive is from the air curtain. It remains a one-stop solution for all the purposes needed at food processing facilities.

Reduce your energy bill with the help of air curtains

To maintain a comfortable temperature within the building while using as little energy as possible is a fundamental motivation for installing an air curtain in almost every business. This also includes factories that prepare food. By acting as a barrier at entrances and preventing the passage of conditioned air from within a mall or building to the outside, air curtains create a microclimate with a distinct temperature gradient. Air curtains are useful in both the winter when they keep the warm air from your heaters inside, and the summer, when they keep the cool air from your air conditioner inside.

To know more about Air Curtains visit: www.mitzvah.in or book your order by dialing 9211092110.