SHEET METALS

We manufacture top quality sheet metal for our customers.

Formation of sheet metal includes an extensive variety of procedures that fabricate parts for a tremendous measure of purposes, both seen and inconspicuous. Sheet metal alludes to metal that has a high surface zone to volume ratio. Sheet metal work stock, utilized for sheet metal procedures, is typically shaped by rolling and comes in loops.

1) Punching

We use the latest software to run the MURATEC Make CNC Turret Punch.

CAMPATH G4 is an “All-around” CAD/CAM system that is easy to operate and is designed to work alongside the WINDOWS operating system. |

| CNC Turret Punch |

| MAKE |

Muratec, Japan |

| Capacity |

20 KN |

| Sheet Thk |

6.35 mm |

| Sheet Size |

1250 X 5000 mm |

| Station |

28 |

| Indexable |

4 |

| Speed |

285 Hits per Min |

| Accuracy |

0.1 mm |

Hydraulic Press

| Bed Size |

1000 X 1250 mm |

| Capacity |

80 Ton |

Power Press

| Capacity |

30 Ton |

# 2 Nos |

|

|

05 Tons |

# 1 Nos |

|

|

|

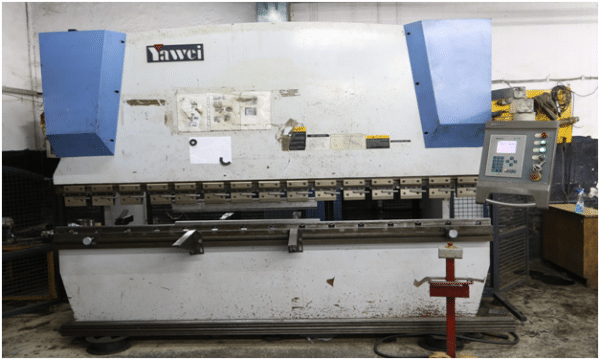

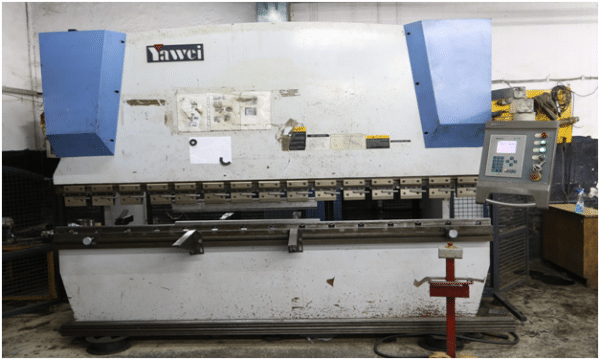

2) Bending

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses. |

|

| NC Bending Machine |

| MAKE |

Yawei |

| Capacity |

110 Ton |

| Controller |

Delem DA41 |

| Bed Size |

3100 mm |

| Sheet Thk |

6.35 mm |

| Sheet Size |

1250 X 5000 mm |

| Station |

28 |

| Indexable |

4 |

| Speed |

285 Hits per Min |

| Accuracy |

0.1 mm |

| Tool Capabilities |

| V Openings Multi V |

Segmented |

| Punch Gooseneck |

Normal |

| Special Tools Hemming |

Offset |

|

3) Shearing

Shearing, also known as die cutting, is a process which cuts stock without the formation of chips or the use of burning or melting. Strictly speaking, if the cutting blades are straight the process is called shearing; |

Shearing Machine

| MAKE |

Yawei |

| Capacity |

6mm X 3200 mm |

| Controller |

Estun E 10 |

| Max Length |

3200 mm |

| Back Gauge |

800 mm |

| Max Thickness |

6 mm |

|

|

4) Welding

Welding which is the process of joining two metallic components for the desired purpose, can be defined as the process of joining two similar or dissimilar metallic components with the application of heat, with or without the application of pressure and with or without the use of filler metal. |

|

Welding Processes

| TIG Welding |

1 Nos |

| MIG Welding |

2 Nos |

| Spot Welding |

1 Nos |

|

5) Assembling

|

| Assembly Lines |

| Type |

Conveyor |

| Motion |

Manual |

| Lines |

3 Nos |

| Station / Line |

6 Nos. |

|

|